Buy Discount Bulk Gravel Bag Transportation Manufacturers Suppliers - Brown paper bag – Zhensheng

Buy Discount Bulk Gravel Bag Transportation Manufacturers Suppliers - Brown paper bag – Zhensheng Detail:

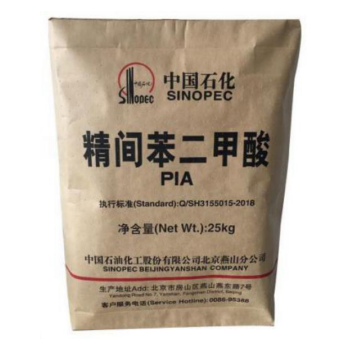

Brown paper bag

Kraft paper bag is a packaging container made of composite materials or pure kraft paper. It is non-toxic, tasteless, non-polluting, low-carbon and environmentally friendly. It meets national environmental protection standards. It has high strength and high environmental protection. It is currently one of the most popular environmentally friendly packaging materials in the world. Kraft paper bags are made of wood pulp paper as the base material. The colors are divided into white kraft paper and yellow kraft paper. The paper can be coated with a layer of PP material to play a waterproof role. The strength of the bag can be made from 1 to 6 layers according to customer requirements. , Printing and bag making are integrated. The opening and back cover methods are divided into heat sealing, paper sealing and paste bottom.

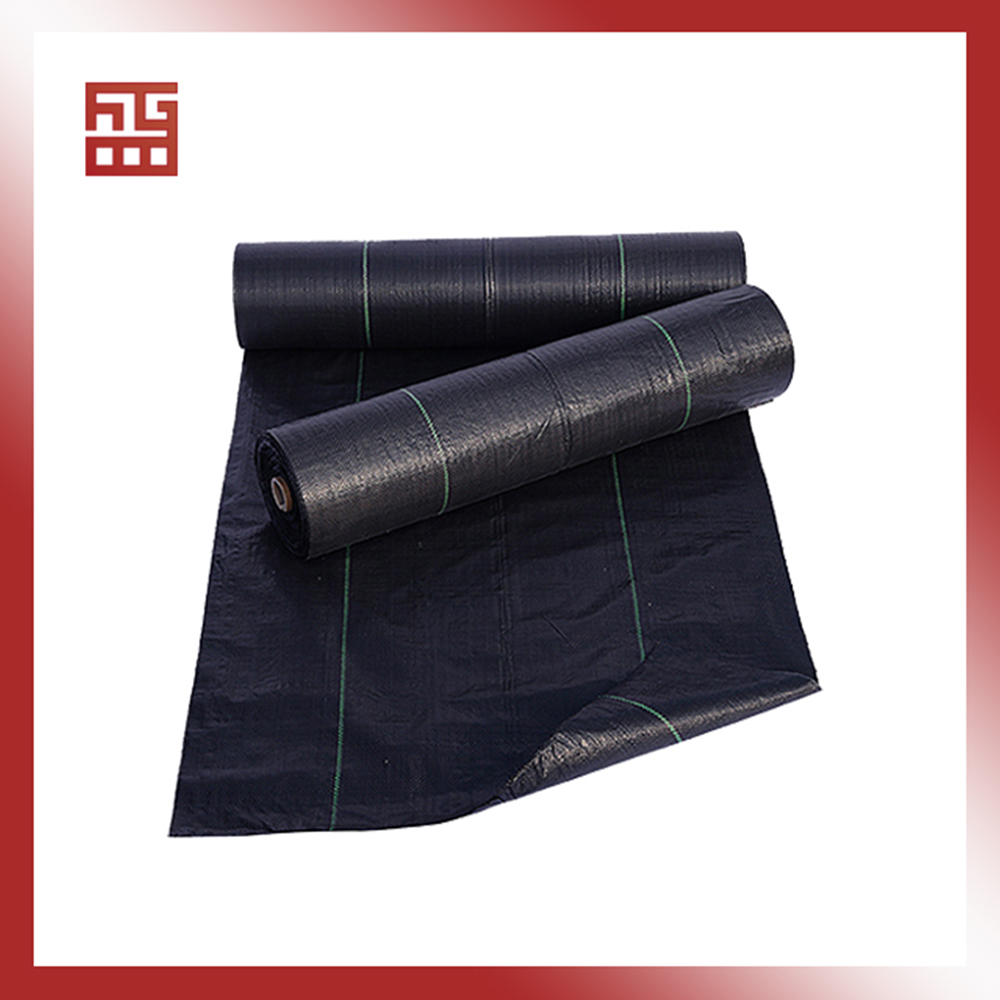

The drawing breaking force of woven bag is a link in the strength control of woven bag. The method to control the drawing breaking force is to control the proportion of raw materials, the cooling forming of diaphragm and the drawing tensile strength.

The manufacturing method is related to the environment and the material. The filler is one of the main components of the raw material proportion, which can improve the physical properties of the brush and reduce the cost. When the electric power of the electric cap increases, the tensile strength of the brush will gradually decrease. This is because the main component of the filling masterbatch is calcium carbonate, which has no tension, Dispersed in the gap of polyolefin polymer chain, there is no great influence on the drawing tensile strength, so as to improve the drawing stiffness. When the addition amount is more than 20% – 25%, the charging masterbatch will over occupy the position of the polymer chain and hinder the elastic deformation of the polymer, so that the polymer chain can not be fully increased along the longitudinal external force.

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Buy Discount Bulk Gravel Bag Transportation Manufacturers Suppliers - Brown paper bag – Zhensheng , The product will supply to all over the world, such as: UK, Istanbul, Holland, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.